UGent researchers open the groundbreaking super-dry reforming (SDR) pilot plant

Researchers at the University of Ghent have achieved a breakthrough by disrupting chemical equilibrium in a scaled-up CO2 recycling process. This milestone is crucial for advancing technologies aimed at reducing atmospheric CO2 emissions and tackling climate change. To showcase the feasibility and scalability of their groundbreaking innovation, the researchers have developed the super-dry reforming (SDR) pilot plant.

“Twenty years ago, I started my research on chemical looping processes”, says Vladimir Galvita, professor at UGent. “These looping processes are crucial for intensifying industrial processes, as they are not bound by chemical equilibrium, unlike catalytic processes. By splitting a chemical reaction into different steps, unprecedented high conversions can be achieved.”

During his PhD, Lukas Buelens, now a postdoctoral researcher at UGent-FWO, developed a chemical looping process called super-dry reforming. This technology uses two greenhouse gases, methane and CO2, and converts them into building blocks for sustainable fuels and chemicals.

This phase is crucial because it allows researchers to test their innovations on a large scale, under real conditions, before the technology can be implemented on an industrial scale.

For scaling up of the technology, the research team received financial support from the Flemish government's Moonshot program. “Moonshot projects like super-dry reforming bridge the gap between research and commercialization by providing the necessary support for experimental scaling and demonstration. This phase is crucial because it allows researchers to test their innovations on a large scale, under real conditions, before the technology can be implemented on an industrial scale”, says Tine Schaerlaekens, managing director of Catalisti.

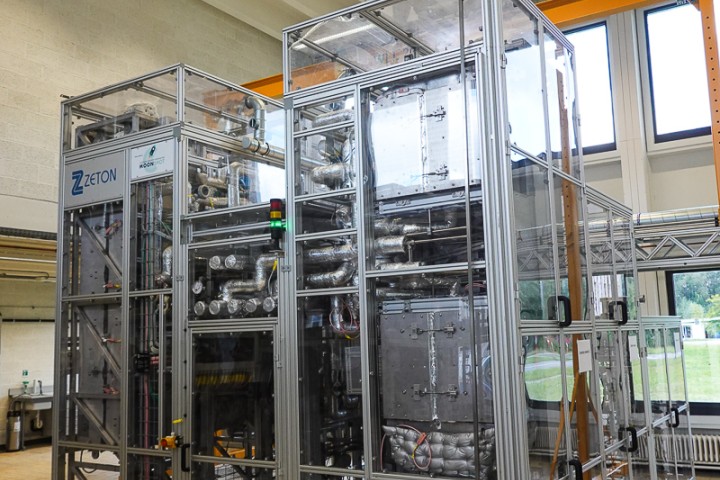

Designing and building the pilot

In 2020, the technical team from the Laboratory for Chemical Technology (LCT) began working on the realization of the pilot setup. “The first step was to understand and list the various requirements of the setup. In addition, we had to take into account all the safety standards maintained by the lab. In collaboration with Zeton, one of the world leaders in designing and building pilot setups, we were able to elevate the design to a higher level.” However, setbacks also occurred, according to Bert Depuydt, technical coordinator of LCT: “Due to the COVID-19 pandemic and the war in Ukraine, the price of aluminum doubled between the quotation and the final construction of the setup. Additionally, several electronic components were unavailable due to a global chip shortage.”

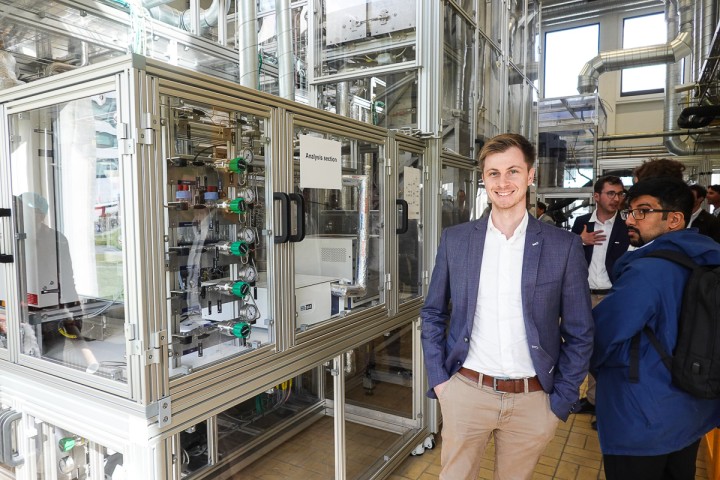

Michiel Van Cauwelaert, PhD researcher at UGent-FWO, was co-responsible for the startup of the setup. “During the first years of my PhD, I gained experience with a lab-scale test setup. Both in terms of data processing and developing an experimental protocol, I now faced challenges rarely encountered at the lab scale due to the size and complexity of the pilot setup. After a four-month startup phase, we were finally able to conduct the first reactive experiments in May. Thanks to the knowledge we’ve gathered over the past few years about the super-dry reforming process and the excellent design of the setup, we immediately achieved conversions in our first experiments that were 10% higher than the gas-phase equilibrium conversion. Something I had always been taught was impossible, but which we have now also demonstrated on a pilot scale. This is therefore a very significant milestone in the development of new technologies to reduce CO2 emissions in the atmosphere and combat climate change.”

Contributing to a sustainable industry

Kevin Van Geem, professor at UGent and director of the Center for Sustainable Chemistry, affirms the importance of this milestone. "Twenty years ago, the Laboratory for Chemical Technology (LCT) changed its name from the Laboratory for Petrochemical Engineering to LCT. The group grew exponentially, and at the same time, the focus shifted from petrochemical applications to many different research domains rooted in sustainable development. Super-dry reforming fits perfectly within this strategy of developing and scaling new technologies, thereby contributing to a more sustainable chemical industry."